Choosing the Right Roller Lever Valve: Factors to Consider for Optimal Performance

Posted by Airmax Pneumatics on March 20th, 2024

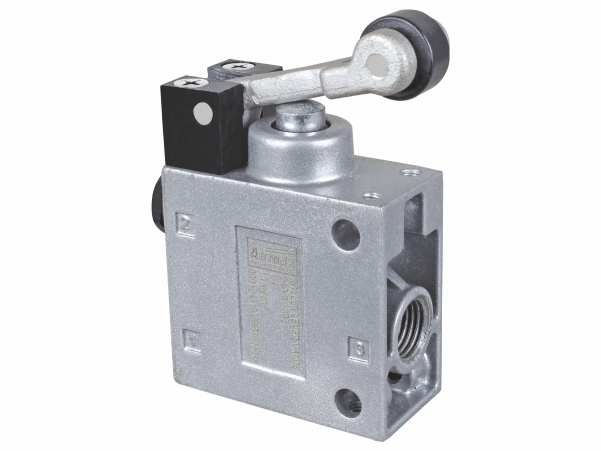

Roller lever valves are essential components in various industries, offering precise control over fluid flow. Here's a breakdown of their key components and functions:

-

Roller Lever: The lever, typically made of metal or plastic, acts as the primary actuator for the valve.

-

Valve Body: This houses the internal components and provides the connection points for fluid flow.

-

Seals: Essential for preventing leaks, seals ensure proper closure when the valve is not in use.

-

Roller: Mounted on the lever, the roller facilitates smooth actuation, reducing friction and wear.

-

Spring: Provides the necessary force to return the lever to its resting position after actuation.

-

Ports: Inlet and outlet ports regulate the flow of fluids through the valve.

Functions:

-

Regulates fluid flow in various industrial applications.

-

Enables precise control and adjustment.

-

Facilitates quick on/off operation.

For the Best Roller Lever Valve in Ahmedabad, consider factors like durability, reliability, and compatibility with your specific application requirements.

Assessing Operating Conditions: Temperature, Pressure, and Media Compatibility

In selecting the best roller lever valve in Ahmedabad, it's essential to thoroughly assess operating conditions to ensure optimal performance and longevity. Here's a breakdown:

-

Temperature: Evaluate the temperature range within which the valve will operate to prevent material degradation or malfunction.

-

Pressure: Determine the maximum and minimum pressure levels the valve will encounter to avoid leaks or damage.

-

Media Compatibility: Assess the compatibility of the valve materials with the media it will handle to prevent corrosion or contamination.

Considering these factors ensures the chosen roller lever valve meets the specific requirements of Ahmedabad's industrial settings, enhancing efficiency and reliability. When shopping for the best roller lever valve in Ahmedabad, prioritize models that excel in temperature resistance, pressure tolerance, and media compatibility to guarantee seamless operation in diverse applications.

Flow Rate Requirements: Matching Roller Lever Valve Specifications

When selecting roller lever valves, ensuring they meet the flow rate requirements is crucial for optimal performance. Here's a brief guide on how to match specifications:

-

Evaluate Flow Rate Needs: Determine the required flow rate for your application, considering factors like pressure, fluid viscosity, and system requirements.

-

Check Valve Specifications: Examine the specifications provided by the manufacturer to ensure the valve's flow rate capabilities align with your needs.

-

Consider Pressure Ratings: Verify that the roller lever valve can handle the pressure conditions within your system without compromising flow rate.

-

Look for Quality Construction: Opt for roller lever valves known for their durability and precision engineering to maintain consistent flow rates over time.

-

Test Compatibility: Before installation, conduct compatibility tests to confirm that the valve meets the desired flow rate under actual operating conditions.

For the Best Roller Lever Valve in Ahmedabad, prioritize options that not only meet but exceed your flow rate requirements while offering reliability and longevity.

Material Selection: Impact on Durability, Corrosion Resistance, and Chemical Compatibility

In selecting materials for various applications, understanding their impact on durability, corrosion resistance, and chemical compatibility is paramount. Here’s a breakdown:

-

Durability: Material choice significantly affects the lifespan and robustness of a product or structure. Factors such as mechanical strength, wear resistance, and fatigue properties play crucial roles.

-

Corrosion Resistance: Certain materials excel in resisting corrosion, safeguarding against degradation due to environmental exposure or chemical reactions. Stainless steel, for instance, offers remarkable corrosion resistance in various environments.

-

Chemical Compatibility: Compatibility with specific chemicals is vital, especially in industrial settings. Materials must withstand exposure to acids, alkalis, solvents, and other corrosive substances without undergoing detrimental changes.

Considerations of these factors are particularly relevant in industries such as manufacturing, construction, and engineering. For instance, when seeking the best roller lever valve in Ahmedabad, material selection will directly impact its performance and longevity.

Choosing the Right Roller Lever Valve for Your Application

Selecting the perfect valve for your application hinges on three key factors: durability, corrosion resistance, and chemical compatibility. The material plays a critical role in all three.

Durability:

Corrosion Resistance:

-

Match the valve material to the surrounding environment.

-

For harsh chemicals, explore options like PVC or CPVC.

Chemical Compatibility:

-

The valve material must be inert to the fluids it handles.

-

Improper selection can lead to leaks, breakdowns, and safety hazards.

For top-quality roller lever valves in Ahmedabad, look no further than Best Roller Lever Valve in Ahmedabad (consider replacing with your company name). Our expert team can help you choose the ideal valve material for your specific needs, ensuring long-lasting performance and secure operation.

Environmental Considerations: Factors Affecting Performance in Various Settings

Temperature Extremes:

-

High temperatures can affect material integrity and fluid properties, potentially leading to leakage or failure.

-

Low temperatures may cause viscosity changes, impacting fluid flow and valve operation.

Humidity Levels:

-

Excessive moisture can lead to corrosion and rust, compromising valve functionality over time.

-

Extremely dry conditions might increase friction, hindering smooth valve operation.

Chemical Exposure:

-

Exposure to corrosive substances can degrade valve materials, necessitating corrosion-resistant options.

-

Compatibility with specific chemicals is crucial to prevent chemical reactions and maintain performance.

Atmospheric Pressure:

Particulate Contamination:

-

Presence of debris or contaminants can obstruct valve mechanisms, causing malfunctions.

-

Regular maintenance and filtration systems are essential to mitigate the risk of blockages.

Consider these factors when selecting the Best Roller Lever Valve in Ahmedabad to ensure optimal performance in diverse environmental conditions.

Budget Constraints: Balancing Cost and Quality in Roller Lever Valve Selection

When working within budget constraints, choosing the right roller lever valve becomes a critical decision. You want a valve that delivers reliable performance without breaking the bank. Here's how to strike that balance:

Identify Application Needs:

-

Pressure and flow rate requirements of your system.

-

Desired material compatibility (e.g., brass, stainless steel).

Prioritize Key Features:

-

Durability and lifespan for long-term cost savings.

-

Ease of maintenance to minimize downtime.

-

Reputation of the manufacturer for quality.

The cheapest valve might not be the most cost-effective in the long run. By considering these factors, you can select a valve that optimizes both performance and value for your project.

Ease of Installation and Maintenance: Streamlining Operations for Efficiency

In today's fast-paced industrial landscape, efficiency is paramount. Ensuring smooth operations often begins with the installation and maintenance processes. Here's how prioritizing ease of installation and maintenance can streamline operations:

-

Reduced Downtime: Simplified installation means quicker setup, minimizing downtime and ensuring continuous production.

-

Cost Savings: Easy maintenance translates to fewer resources spent on repairs and replacements, resulting in long-term cost savings.

-

Enhanced Productivity: Streamlined processes free up time and resources, allowing teams to focus on core tasks, ultimately boosting productivity.

-

Improved Safety: Simple installation and maintenance procedures contribute to a safer work environment, reducing the risk of accidents.

-

Customer Satisfaction: Quick installation and minimal maintenance requirements lead to happier customers, fostering long-term relationships and loyalty.

For businesses in Ahmedabad seeking operational efficiency, investing in the best roller lever valve in Ahmedabad can significantly contribute to achieving these benefits while ensuring seamless workflow.

Compatibility with Existing Systems: Integrating Roller Lever Valves Seamlessly

Upgrading your system with roller lever valves shouldn't require a complete overhaul. Here's why roller lever valves are ideal for seamless integration:

-

Adaptable Mounting: Roller lever valves come in various mounting styles, including flange, in-line, and sub-base. This allows them to fit existing piping configurations, minimizing the need for major modifications.

-

Universal Actuation: Many roller lever valves accept a wide range of actuation options, like solenoid coils and pneumatic actuators. This ensures compatibility with your current control system, reducing the need for additional equipment.

-

Simplified Maintenance: Roller lever valves feature a simple design with minimal moving parts. This translates to easier maintenance and reduces downtime during integration.

By prioritizing compatibility during the selection process, you can ensure a smooth transition to roller lever valves. For the best roller lever valve options in Ahmedabad, look no further than Best Roller Lever Valve in Ahmedabad.