Comparing Compact Pneumatic Air Cylinders to Other Actuators: A Comprehensive Guide

Posted by Airmax Pneumatics on April 9th, 2024

Actuators are the workhorses of the mechanical world, silently converting energy into controlled motion. These devices take various forms, but their core function remains the same: translating an external signal, often electrical, hydraulic, or pneumatic, into physical movement.

-

The Powerhouse of Movement: Imagine a machine – an industrial press, a robotic arm, or even your car brakes. Actuators are the unseen muscles that enable these machines to perform their tasks.

-

Types of Actuators: The world of actuators is vast, with each type suited for specific needs. Electric actuators offer precise control, while hydraulic actuators provide immense force. Pneumatic actuators, powered by compressed air, find favor for their simplicity and clean operation.

-

Finding the Right Fit: Choosing the right actuator depends on the application. Factors like force requirements, speed, and environmental conditions all play a role.

For high-quality compact pneumatic air cylinders in Ahmedabad, consider exploring reliable suppliers in your area. These versatile actuators offer clean operation and precise control, making them ideal for various industrial applications.

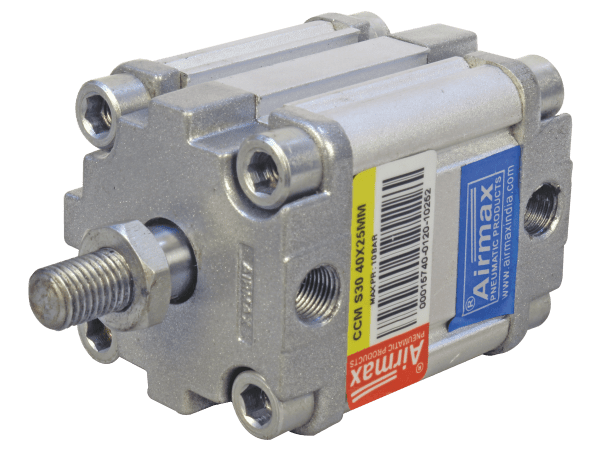

Defining Compact Pneumatic Air Cylinders: Features and Functionality

Compact pneumatic air cylinders are essential components in various industrial applications, offering efficient linear motion with compressed air power. Here are the key features and functionalities:

-

Space-Saving Design: Compact cylinders are designed to occupy minimal space while delivering optimal performance, making them ideal for applications with limited space constraints.

-

Lightweight Construction: These cylinders are typically constructed with lightweight materials such as aluminum or stainless steel, ensuring ease of installation and handling.

-

High Precision: Compact air cylinders offer precise and repeatable linear motion, contributing to enhanced accuracy in automated processes.

-

Versatile Mounting Options: They come with versatile mounting options, including direct mounting, foot mounting, or bracket mounting, facilitating flexible installation according to specific requirements.

-

Durable and Reliable: Compact pneumatic cylinders are engineered for durability and reliability, ensuring long-lasting performance even in demanding industrial environments.

For high-quality compact pneumatic air cylinders in Ahmedabad, trust Airmax Pneumatic, providing reliable solutions for industrial automation needs.

Electromechanical Actuators: Differences in Operation and Application

Choosing the right actuator for your project depends on the specific needs of your application. Here's a quick breakdown of the key differences between electromechanical and pneumatic actuators:

Operation:

-

Electromechanical: Relies on electric motors to convert electrical energy into precise mechanical motion. Offers high controllability and works well with electronic control systems.

-

Pneumatic: Uses compressed air to generate force and movement. Offers high power and speed but can be less precise.

Applications:

-

Electromechanical: Ideal for applications requiring clean operation, precise control, and integration with electronics. Common in robotics, 3D printers, and automated assembly lines.

-

Pneumatic: Well-suited for high-force tasks in industrial settings like factory automation and material handling.

For pneumatic solutions, consider searching for "High Quality Compact Pneumatic Air Cylinder in Ahmedabad" to find local suppliers that meet your project requirements.

Remember, electromechanical actuators offer precision and control, while pneumatics provide raw power. Choose the one that best suits your application's needs.

Size and Weight Considerations: How Compact Pneumatic Air Cylinders Stand Out

When it comes to selecting pneumatic air cylinders, size and weight considerations play a crucial role, especially in applications where space is limited. Compact pneumatic air cylinders offer several advantages that make them stand out in this aspect:

-

Space Efficiency: Compact cylinders are designed to occupy minimal space, making them ideal for applications with tight constraints.

-

Lightweight Construction: Their small size translates to lower weight, enabling easier handling and installation.

-

Enhanced Portability: Compact cylinders are more portable, facilitating transportation and deployment in various settings.

-

Reduced Material Consumption: Due to their smaller dimensions, these cylinders require less material, contributing to cost savings and environmental benefits.

-

Versatile Applications: Despite their compact size, these cylinders deliver high performance across a wide range of applications.

For high quality compact pneumatic air cylinders in Ahmedabad, consider our range of products tailored to meet your specific needs.

Speed and Precision: Evaluating Performance Across Actuator Types

In the realm of industrial automation, the evaluation of actuator performance is paramount, particularly concerning speed and precision. Actuators serve as the muscle behind various automated systems, influencing efficiency and productivity. Here's a breakdown of key points to consider when assessing performance across different actuator types:

Speed:

-

Hydraulic actuators: Known for their high force output but relatively slower speed.

-

Pneumatic actuators: Offer faster response times compared to hydraulics due to compressed air usage.

-

Electric actuators: Provide precise control and variable speed options, suitable for applications requiring both speed and accuracy.

Precision:

-

Electric actuators: Excel in precision tasks due to their ability to precisely control position and velocity.

-

Pneumatic actuators: Offer decent precision, especially with advanced control systems.

-

Hydraulic actuators: Typically used for high-force applications rather than precision tasks.

Considering the need for both speed and precision, businesses may find the solution they seek in a High-Quality Compact Pneumatic Air Cylinder in Ahmedabad, marrying the benefits of speed and accuracy in their automated processes.

Power Requirements: Energy Efficiency of Compact Pneumatic Air Cylinders vs. Others

Choosing the right actuator for your project requires considering factors like force, speed, and most importantly, energy use. Here's a quick comparison:

Pneumatic Cylinders:

Electric Actuators:

-

Highly Efficient (80%) - translates to lower running costs

-

Precise control and clean operation

-

May require additional wiring and control systems

For space-saving applications that prioritize efficiency, consider high-quality compact pneumatic air cylinders. These actuators offer a balance between footprint and compressed air use. To find reliable options in Ahmedabad, look for suppliers specializing in High Quality Compact Pneumatic Air Cylinders in Ahmedabad.

Environmental Factors: Suitability in Various Operating Conditions

When selecting a High Quality Compact Pneumatic Air Cylinder in Ahmedabad, consider the environmental conditions it will operate in. Here's a breakdown of key factors:

-

Temperature: Cylinders have a designated operating temperature range. Extreme heat or cold can affect seal performance and shorten lifespan.

-

Humidity: Excess moisture can lead to rust or corrosion. Opt for corrosion-resistant materials if humidity is a concern.

-

Dust and Debris: A dirty environment can damage internal components. Look for cylinders with protective features like wipers or bellows.

-

Chemicals: Exposure to harsh chemicals may require special materials or surface treatments for compatibility.

By considering these environmental factors, you can ensure your High Quality Compact Pneumatic Air Cylinder in Ahmedabad functions reliably for years to come.